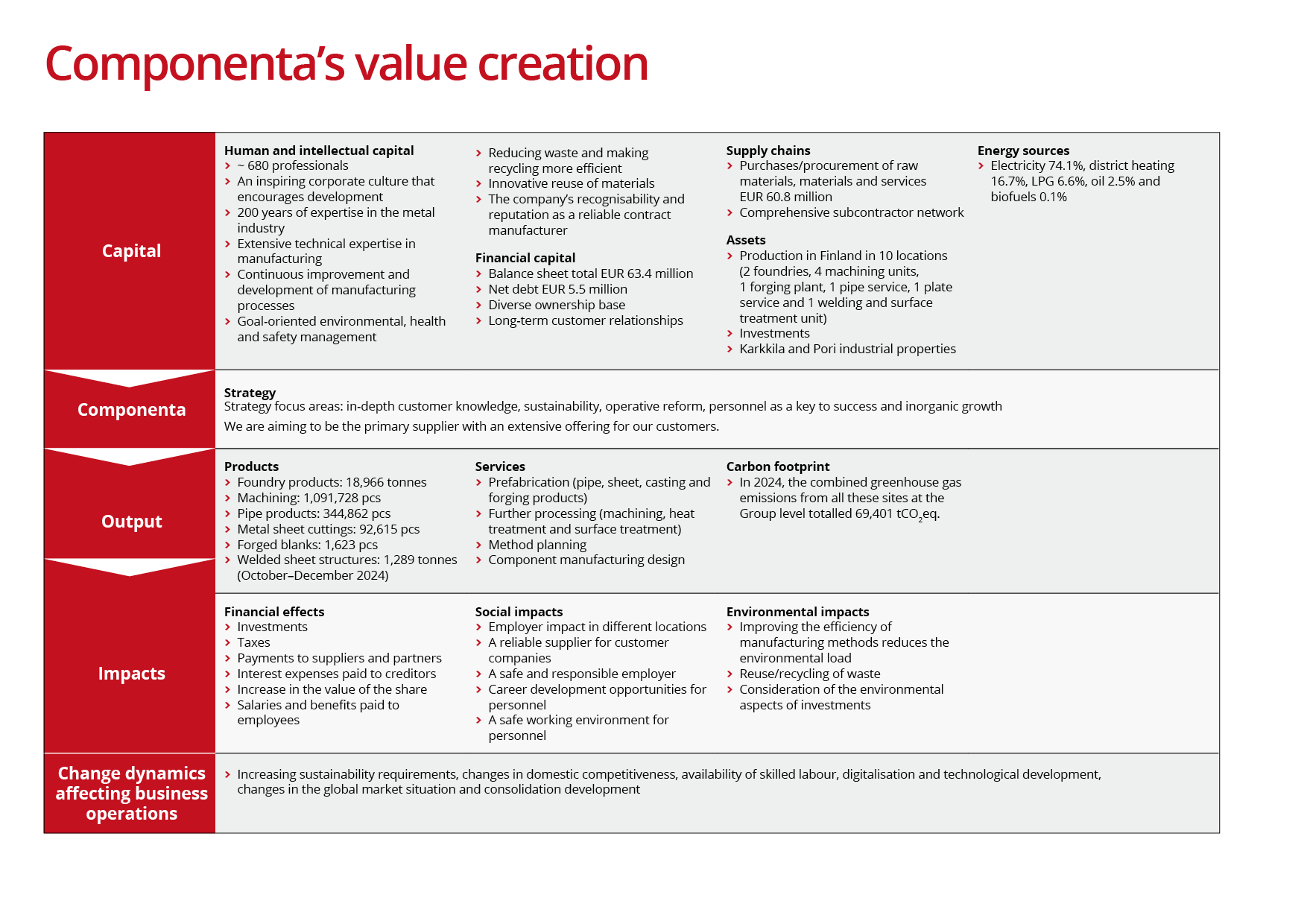

Sustainability

Responsible operations and sustainable development are a key part of Componenta’s business.

The company’s values – openness, honesty and appreciation – and its strategy and operating methods lay the foundation for its responsible operations. Sustainability is considered in the company’s short-term and long-term planning and development. Componenta’s management sets sustainability goals annually. The company’s progress towards these goals is regularly monitored and analysed.

You can also read about Componenta’s sustainability statement in our latest annual review.

Componenta recognises the impact of its business operations on the surrounding society and its stakeholders. Responsibility for the environment and caring for personnel are particularly important in the company’s field of operation. In terms of the product portfolio, the production of cast components is particularly energy-intensive, and the production process generates significant amounts of surplus sand and dust as a by-product. Due to the personnel-intensive nature of the industry, personnel costs and investments in employees’ wellbeing and competence development have a significant impact on the company’s success. The company respects its employees’ rights, freedom of association and right to collective bargaining, and conducts its business under safe working conditions. The company has zero tolerance for forced labour, child labour and discrimination.